Healthcare Jars & Closures – Injection Moldings

Free!$0.00

Our fully automated, touchless injection molding assembly and packing provides the highest quality jars. Mix and match closure options or custom colors to create your signature brand. For a more sustainable choice, we offer up to 100% PCR and HEMP plastic alternatives. For tamper evidence, a variety of induction seal liners are available in our closures. Complete your package with our in-house decorating options.

Decoration Capabilities

- High-speed Pressure Sensitive top of closure labeling

- High-speed Pressure Sensitive full wrap labeling

- High-speed Pressure Sensitive front and back labeling

- High-speed Pressure Sensitive spot labeling of jar bottom

- Pad Printing

UV inhibitors and custom colors available.

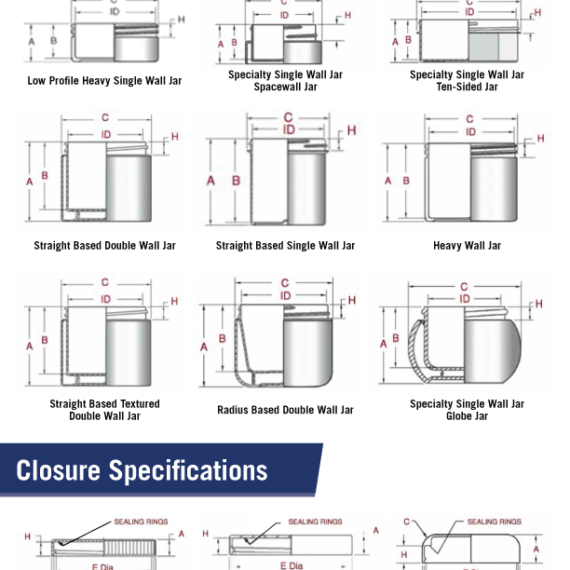

Low Profile

|

Size |

Neck |

Mat |

OFC |

A |

B |

C |

ID |

H |

QTY/Carton |

|

1 oz |

70mm |

PP |

60 +/- 3.0cc |

.908 +/- .015 |

.770 +/- .015 |

2.843 +/- .015 |

2.490 +/- .015 |

.408 +/- .015 |

462 |

|

2 oz |

70mm |

PP |

89 +/- 5cc |

1.295 +/- .015 |

1.183 +/- .015 |

2.836 +/- .015 |

2.490 +/- .015 |

.408 +/- .015 |

297 |

|

4 oz |

89mm |

PP |

174 +/- 9cc |

1.49 +/- .020 |

1.348 +/- .015 |

3.624 +/- .015 |

3.242 +/- .015 |

.535 +/- .015 |

160 |

|

6 oz |

89mm |

PP |

1.965 +/- .015 |

1.853 +/- .015 |

3.64 +/- .015 |

3.24 +/- .015 |

.530/500 +/- .015 |

120 |

Straight-Based Single Wall Jar

| SIZE |

NECK |

MAT |

GRAM WT |

OFC |

A |

B |

C |

ID |

H |

QTY/CARTON |

||||||||||||||||||||||||||||||

| .5 oz |

33mm |

PP |

3.8 +/-.19gr |

15.2 +/- 2.0 cc |

1.140 +/-.012 |

1.089 +/-.012 |

1.241 +/-.024 |

1.05 +/- .015 |

0.359 +/- .015 |

1750 |

||||||||||||||||||||||||||||||

| .875 oz |

33mm |

PP |

6.2 +/-1 gr |

25 +/-1.5 cc |

1.944 +/-.012 |

1.838 +/-.012 |

1.265 +/-.024 |

1.046 +/-.015 |

.406 +/-.034 |

1000 |

|

|||||||||||||||||||||||||||||

| 2 oz |

53mm |

PP |

10.3 +/- 1.0 gr |

75 +/- 4 cc |

1.798 +/- .015 |

1.700 +/- .015 |

2.065 +/- .015 |

1.866 +/- .015 |

.408 +/- .015 |

630 |

|

|||||||||||||||||||||||||||||

| 4 oz |

70mm |

PP |

19.5 +/- 1.5 gr |

174 +/- 7 cc |

2.280 +/- .020 |

2.170 +/- .020 |

2.690 +/- .015 |

2.520 +/- .015 |

.408 +/- .015 |

273 |

|

|||||||||||||||||||||||||||||

| 8 oz |

70mm |

PP |

27.0 +/- 2.0 gr |

268 +/- 7 cc |

3.500 +/- .020 |

3.450 +/- .020 |

2.685 +/- .015 |

2.515 +/- .015 |

.408 +/- .015 |

195 |

|

|||||||||||||||||||||||||||||

| 8 oz |

89mm |

PP |

30.5 +/- 3.0 gr |

321 +/- 16 cc |

2.545 +/- .015 |

2.460 +/- .020 |

3.446 +/- .015 |

3.255 +/- .015 |

535 +/- .015 |

100 |

|

|||||||||||||||||||||||||||||

| 16 oz |

89mm |

PP |

40.5 +/- gr |

491 +/- 10 cc |

3.790 +/- .020 |

3.710 +/- .020 |

3.530 +/- .020 |

3.280 +/- .015 |

.535 +/- .015 |

60 |

||||||||||||||||||||||||||||||

Straight-Based Double Wall

| SIZE |

NECK |

MAT |

GRAM WT |

OFC |

A |

B |

C |

ID |

H |

|

QTY/ CARTON |

|||||||||||||||||||||||||||||

| .5 oz |

48mm |

PP/PP-Matte |

13.0 +/- 1.5 gr |

22 +/- 3 cc |

1.258 +/- .015 |

.795 +/- .015 |

1.260 +/- 0.20 |

1.370 +/- .020 |

.408 +/- .015 |

603 |

||||||||||||||||||||||||||||||

| 1 oz |

53mm |

PP/PP |

17.5 +/- 1.5 gr |

54 +/- 3 cc |

1.580 +/- .015 |

1.200 +/- .015 |

2.200 +/- .015 |

1.855 +/- .015 |

.408 +/- .015 |

|

660 |

|||||||||||||||||||||||||||||

| 2 oz |

58 mm |

PP/PP |

21.5 +/- 2.0 gr |

75 +/- 4 cc |

1.940 +/- .020 |

1.520 +/- .020 |

2.335 +/- .015 |

1.970 +/- .015 |

.408 +/- .015 |

|

288 |

|||||||||||||||||||||||||||||

| 3 oz |

63 mm |

PSP/PP-Matte |

30.1 +/- 1.5 gr |

114 +/- 5 cc |

2.230 +/- .020 |

1.870 +/- .020 |

2.600 +/- .020 |

2.223 +/- .015 |

1.970 +/- .015 |

|

210 |

|||||||||||||||||||||||||||||

| 4 oz |

70 mm |

PP/PP |

38.0 +/- 1.5 gr |

142 +/- 7 cc |

2.410 +/- .015 |

1.950 +/- .015 |

2.900 +/- .015 |

2.500 +/- .015 |

.408 +/- .015 |

|

165 |

|||||||||||||||||||||||||||||

| 6 oz |

70 mm |

PP/PP |

42.2 +/- 2.5 gr |

208 +/- 5 cc |

3.042 +/- .015 |

2.677 +/- .015 |

2.913 +/- .015 |

2.512 +/- .015 |

.408 +/- .015 |

|

170 |

|||||||||||||||||||||||||||||

| 8 oz |

89 mm |

PP/PP |

56.2 +/- 3.0 gr |

280 +/- 14 cc |

2.650 +/- .020 |

2.247 +/- .015 |

3.650 +/- .020 |

3.220 +/- .020 |

.515 +/- .015 |

|

120 |

|||||||||||||||||||||||||||||

| 12 oz | 89 mm | PP/PP | 75.5 +/- 3.8 gr | 375 +/- 7 cc | 3.490 +/- .015 | 3.074 +/- .015 | 3.678 +/- .015 | 3.218 +/- .015 | .535 +/- .015 |

100 |

||||||||||||||||||||||||||||||

Specialty Single Wall Jars

|

Size |

Neck |

Material |

Gram Wt |

OFC |

A |

B |

C |

ID |

H |

QTY/Carton |

|

3/8 oz Spacewall |

38mm |

PP |

5.8 +/- |

14.0 +/- 1.5cc |

.812 +/- .015 |

.720 +/- .020 |

1.700 +/- .015 |

1.250 +/- .015 |

.390 +/- .015 |

1300 |

|

2-5/8 oz Ten Sided |

70mm |

PS |

16.0 +/- |

78.0 +/- 3.0cc |

1.090 +/- .015 |

.960 +/- .020 |

2.860 +/- .020 |

2.484 +/- .015 |

.385 +/- .015 |

350 |

Domed Closures (Smooth or Textured Matte)

|

Size |

Material |

Gram Wt |

A |

B |

H |

T |

E |

QTY/Carton |

|

RC 89 /400 |

PP |

16.4+/-1 gr. |

.690+/-.015 |

3.670+/-.015 |

R.375+/-.015 |

.460+/-.010 |

3.512+/-.008 |

300 |

|

RC 100 /400 |

PP |

24.6+/-1.5gr. |

.912+/-.015 |

4.100+/-.015 |

R.375+/-.015 |

.650+/-.009 |

3.947+/-.009 |

300 |

Smooth Straight Sided Jar Closures

|

Size |

Material |

Gram Wt |

A |

B |

H |

T |

E |

QTY/Carton |

|

H 33 /400 |

PP |

2.2+/-.3gr. |

.435+/-.015 |

1.365+/-.015 |

.381+/-.009 |

1.271+/-.009 |

1.181+/-.009 |

3500 |

|

H 45 /400 |

PP |

4.2+/-.5gr. |

.440+/-.015 |

1.855+/-.015 |

.382+/-.009 |

1.746+/-.007 |

1.654+/-.007 |

1400 |

|

H 48 /400 |

PP |

6.2+/-.5gr. |

.466+/-.015 |

2.038+/-.015 |

.397+/-.009 |

1.880+/-.009 |

1.784+/-.007 |

1742 |

|

H 53 /400 |

PP |

4.4+/-.5gr. |

.455+/-.015 |

2.165+/-.015 |

.400+/-.009 |

2.075+/-.007 |

1.981+/-.007 |

1300 |

|

H 58 /400 |

PP |

5.7+/-.5gr. |

.450+/-.015 |

2.330+/-.015 |

.397+/-.009 |

2.232+/-.007 |

2.138+/-.007 |

1100 |

|

H 63 /400 |

PP |

7.1+/-.5gr. |

.450+/-.015 |

2.600+/-.015 |

.397+/-.009 |

2.469+/-.007 |

2.377+/-.009 |

1100 |

|

H 70 /400 T |

PP |

8.7+/-.5gr. |

.440+/-.015 |

2.905+/-.015 |

.389+/-.009 |

2.754+/-.007 |

2.660+/-.007 |

700 |

|

H 70 /400 A |

PP |

8.5+/-1gr. |

.450+/-.015 |

2.840+/-.015 |

.394+/-.012 |

2.744+/-.007 |

2.650+/-.007 |

700 |

| H 70/ 400 High top | PP | 16.5+/-1.65 gr | .902+/-.015 | 2.884+/-.015 | .397+/-.009 | 2.744+/-.007 | 2.650+/-.007 | 462 |

| H 89/ 400 Textured | PP | 18.8+/-1gr | .610+/-.015 | 3.665+/-.020 | .524+/-.009 | 3.520+/-.008 | 3.400+/-.008 | 300 |

|

H 89 /400 |

PP |

14.8+/-1gr. |

.570+/-.015 |

3.641+/-.015 |

.498+/-.015 |

3.521+/-.009 |

3.410+/-.010 |

300 |

|

H 100 /400 |

PP |

20.0+/-1.5gr. |

.650+/-.015 |

4.070+/-.015 |

.578+/-.010 |

3.940+/-.010 |

3.830+/-.010 |

300 |

Ribbed Sided Smooth Top Jar Closures

|

Size |

Material |

Gram Wt |

A |

B |

H |

T |

E |

QTY/Carton |

|

R 45 /400 |

PP |

4.0+/-.5gr. |

.445+/-.015 |

1.875+/-.015 |

.397+/-.009 |

1.748+/-.007 |

1.654+/-.007 |

1800 |

|

R 48 /400 |

PP |

4.2+/-.4gr. |

.450+/-.015 |

1.990+/-.015 |

.397+/-.009 |

1.880+/-.009 |

1.784+/-.007 |

1600 |

|

R 53 /400 |

PP |

4.6+/-.3gr. |

.450+/-.015 |

2.170+/-.015 |

.397+/-.009 |

2.075+/-.007 |

1.981+/-.007 |

1300 |

|

R 58 /400 |

PP |

6.2+/-.3gr. |

.450+/-.015 |

2.355+/-.015 |

.397+/-.009 |

2.227+/-.007 |

2.132+/-.007 |

1100 |

|

R 63 /400 |

PP |

6.7+/-.5gr. |

.450+/-.015 |

2.600+/-.015 |

.397+/-.009 |

2.469+/-.007 |

2.375+/-.007 |

800 |

|

R 70 /400 |

PP |

1.8+/-1gr. |

.455+/-.015 |

2.850+/-.015 |

.396+/-.011 |

2.744+/-.007 |

2.655+/-.007 |

700 |

|

R 89 /400 |

PP |

16.0+/-.8gr. |

.605+/-.015 |

3.653+/-.015 |

.513+/-.013 |

3.524+/-.008 |

3.404+/-.008 |

300 |